The JGM757KV is an upgrade heavy-duty medium wheel loaders with 5 big upgrades and 35 improvements based on the classic model JGM757K & JGM757KN, which is equipped with spacious and comfortable new cab, machine covering parts and configuration design upgrade. It is a brand new product with beautiful and practicality, optimization and improvement of each system detail.

1. Covering part-Cab

JinGong KV-series wheel loader adopts Jingong developed brand-new cab, which is luxurious, open-view, beautiful and practical.

1.1.Luxurious: Jingong KV-series cab is equipped with luxurious adjustable seats, brand-new operating table and instrument, adjustable directional column and sunshade curtain, cab air conditioner outlet, Bluetooth radio, centralized control box, dry powder fire extinguisher, safety hammer, USB charging, etc.

1.2.Open-view:

1.2.1. The front of cab is using hyperboloid toughened glass, which has wide visual field and good sound insulation performance.

1.2.2. The door is opened to forward, and the width of entrance and exit is increased by 20%. There is no threshold design, which is more convenient for drivers to enter and exit.

1.3.Elegant apperance:

The combination of deep and shallow colors, to create a clean and comfortable cab for drivers who work hard.

1.4.Practical:

1. The cab door is formed by stamping and welding the inner and outer plates, with high technological level, smooth and beautiful overall and good sealing performance.

2. The cab enters from the left side. The right window is equipped with a glass frame that can be pushed up and down, the cab door is fixed by a positioning lock.

2.Covering part - Rear hood

Jingong JGM757KV loader is replaced with a brand-new rear hood, which increases mesh protection, reduces radiator blowing block, reduces hot air backflow, and convenient for cleaning and maintenance.

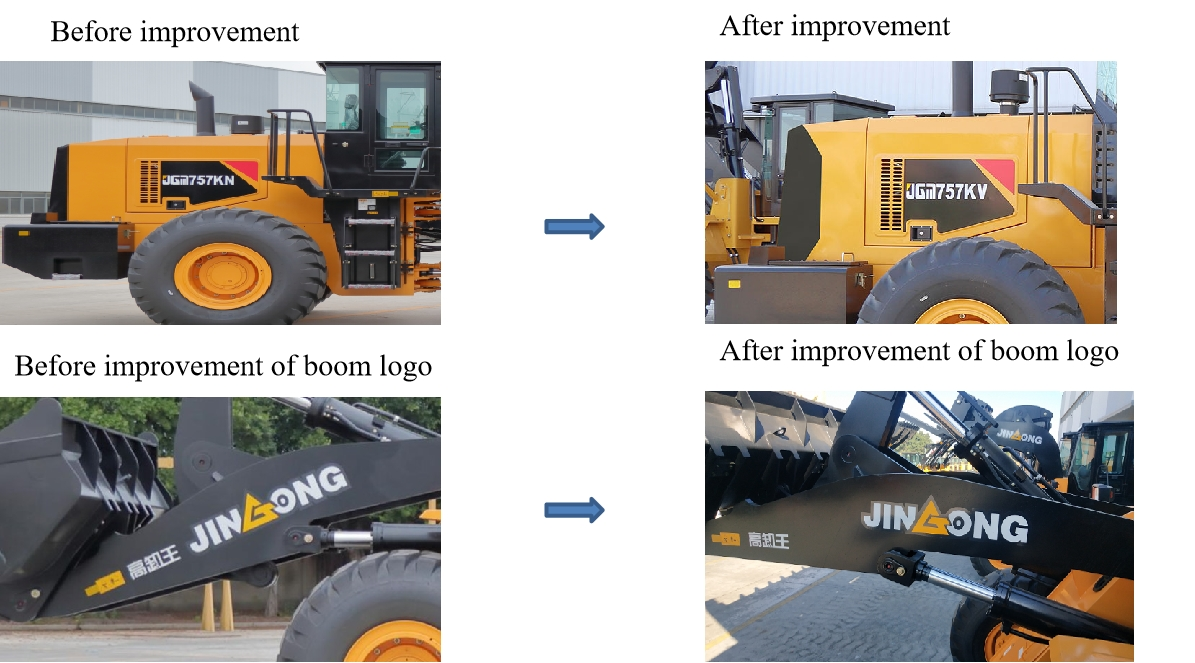

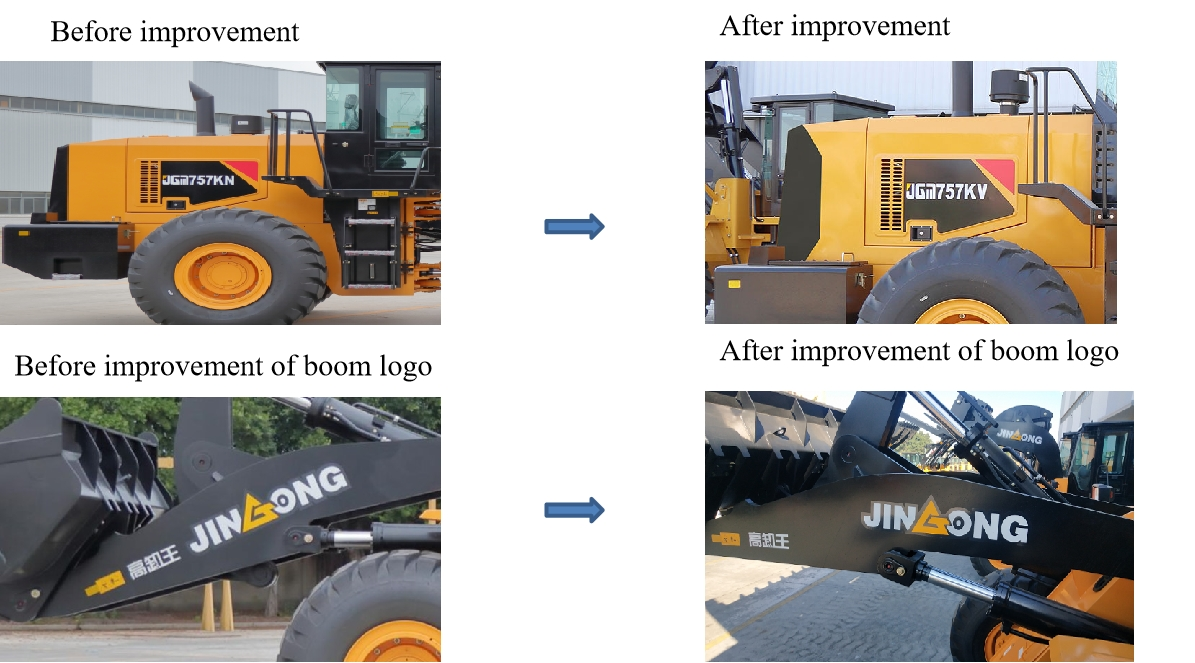

Hood color and logo, boom logo

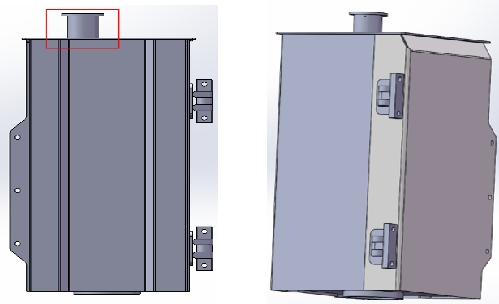

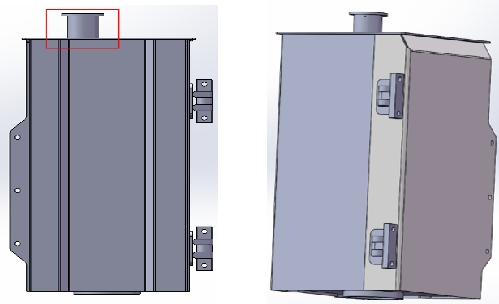

3.Covering part - Oil tank

3.1.1. The capacity of hydraulic oil tank is 280L.

3.1.2. The install point moves to the four ends, and the back plate and the side plate of the frame are tight to reduce the shaking of the fuel tank.

3.1.3. Adopt upper and lower circular oil marks. For checking the oil level when filling oil, which is convenient for adjusting the refueling capacity.

3.2.1. The installation point and fixing method of fuel tank are changed as the hydraulic fuel tank.

3.2.2. The back plate is bent to reduce the welding seams, and the install seat is fixed on the plate with 6mm, so the safety factor is large.

3.2.3. The oil filler is on the outside which convenient to refuel , and the oil can be prevented from shaking and spilling by heightening the oil filler.

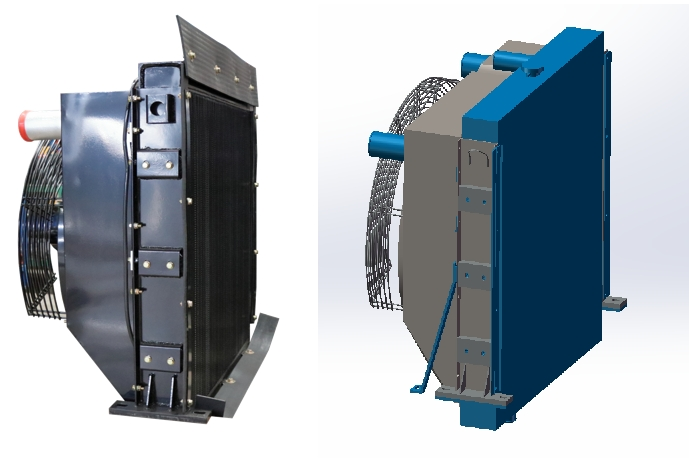

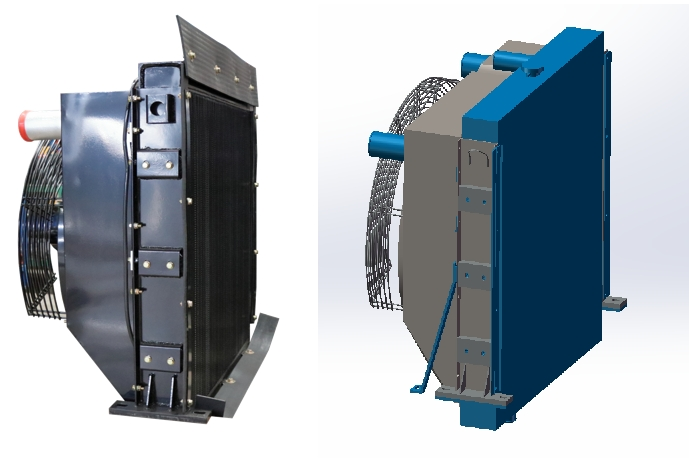

4.Power transmission - Radiator

Jingong Newly Upgrade Model 757KV are Improved and Upgrade Cooling System

The oil dispersion of the double transformer is changed from water cooling to air cooling, and placed at the rear of the radiator. The hydraulic oil dispersion adopts a large single-component shell-and-tube radiator to ensure the normal operation in high temperature environment, and at the same time, to avaided oil mixing between hydraulic oil and transmission oil in cooler.

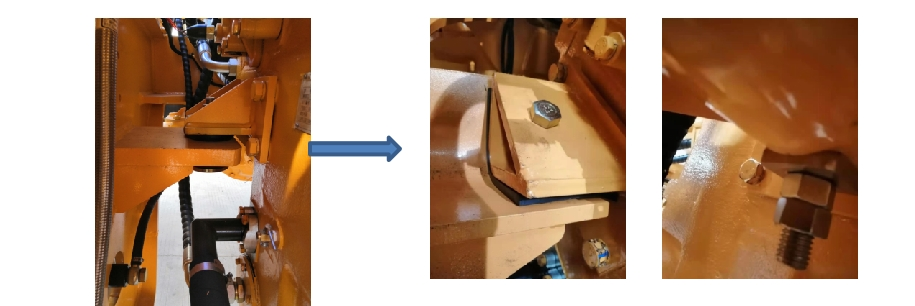

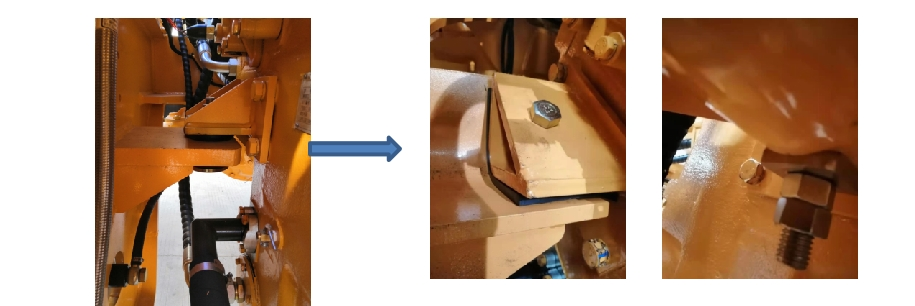

5. Power transmission - Transmission bracket and filter

Transmission bracket improvement:

The transmission bracket is changed from plane to U -shaped absorb shock, and the three -in-one front and rear kinetic energy plays a limiting role.

Filter improvement:

Improve the flow rate and accuracy of the oil filter, and more easy to replacement the filter element.

6.Structural part - Front frame

The front frame is stronger than before.

7.Structural part - Oil filling pipe improved

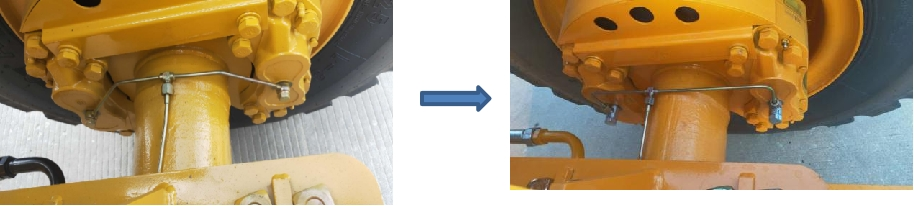

The oil filling pipes of the upper pin shaft from the boom and the rear pin shaft of the bucket cylinder are improved from steel pipes to rubber pipes.

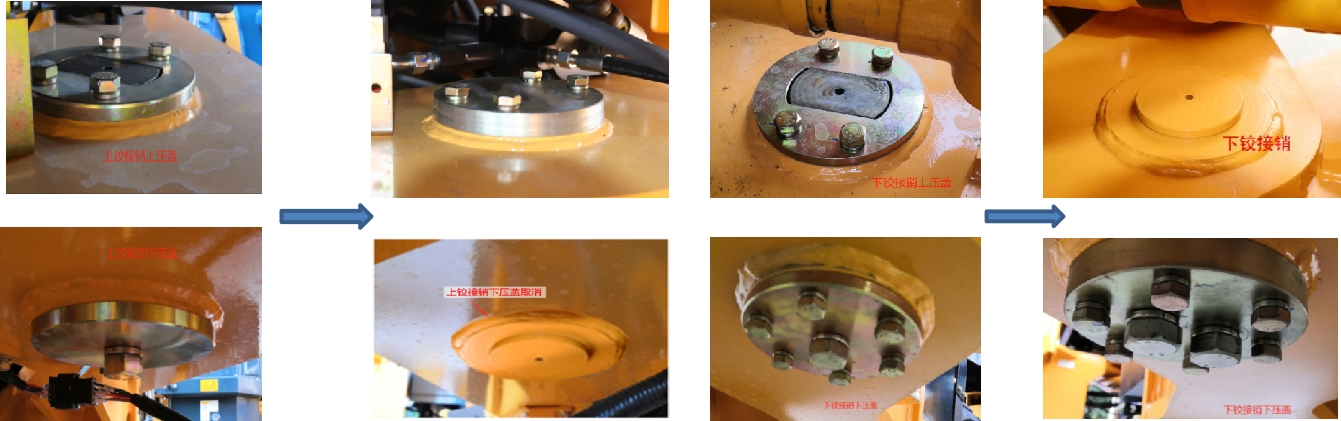

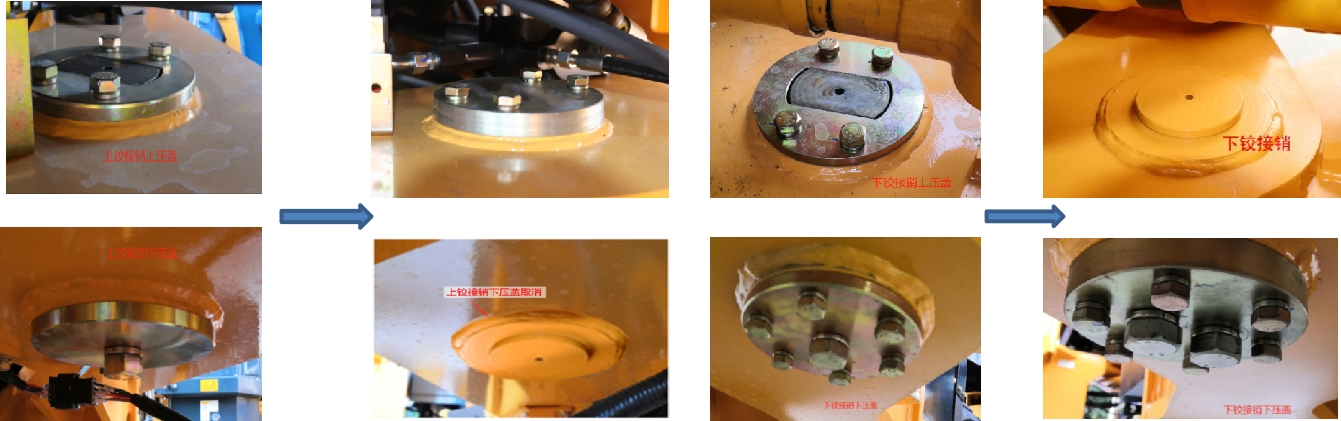

8.Structural part - Up and down hinged pin shaft structure

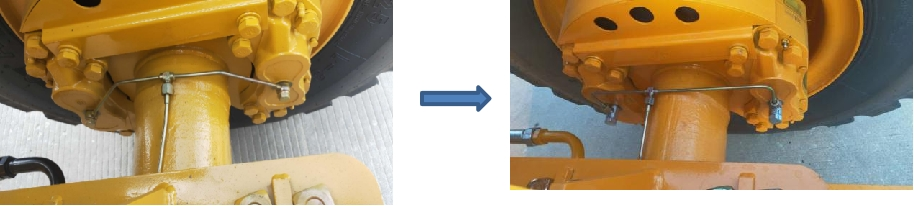

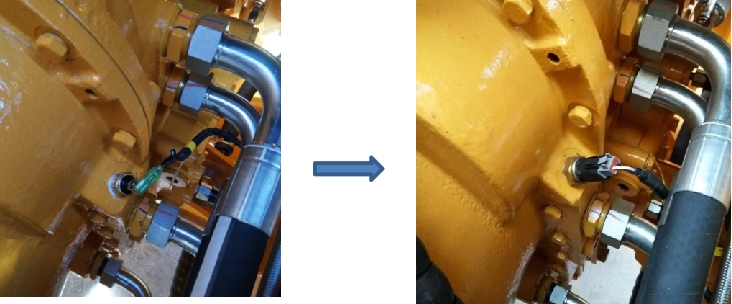

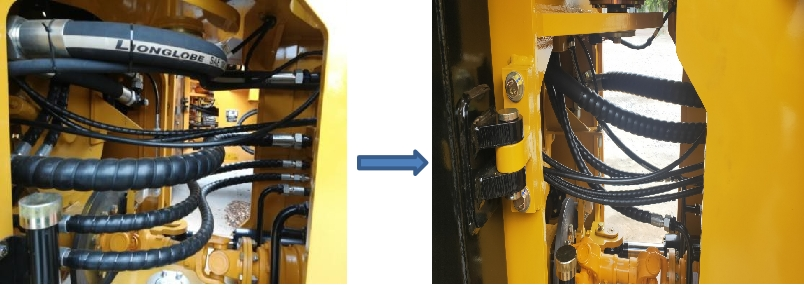

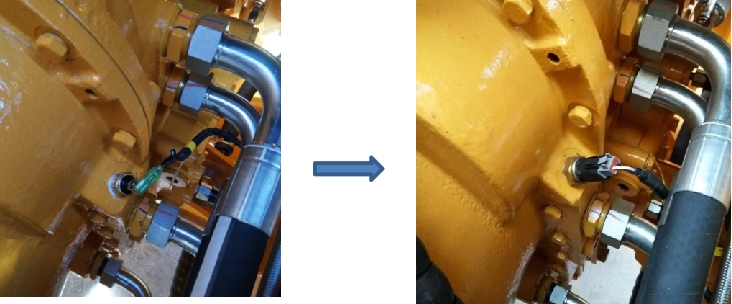

9.Hydraulic system-Pipeline improvement

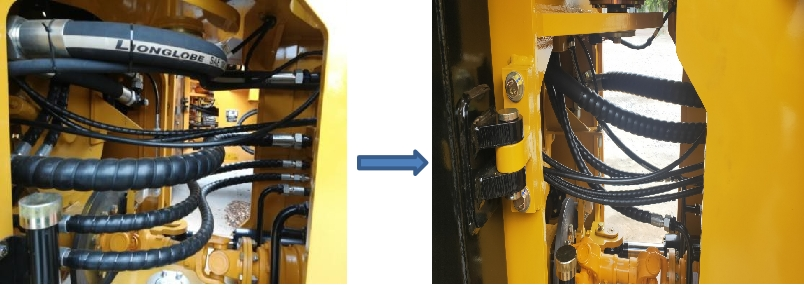

Straightening pipe for middle hinged S-shaped pipeline

The rubber hose with S-shaped direction hinged in the middle, which frequently turns to work, will cause oil leakage at the rubber hose detention place, and the rubber hose itself will also be subjected to bending stress. Change the structure of straight pipe, reduce the stress of rubber hose during steering, and make the arrangement more beautiful.

Simplify of multi-way valve and rotary bucket cylinder pipeline;

The pipeline from the multi-way valve to the bucket cylinder is changed into a rubber hose to simplify the pipeline.

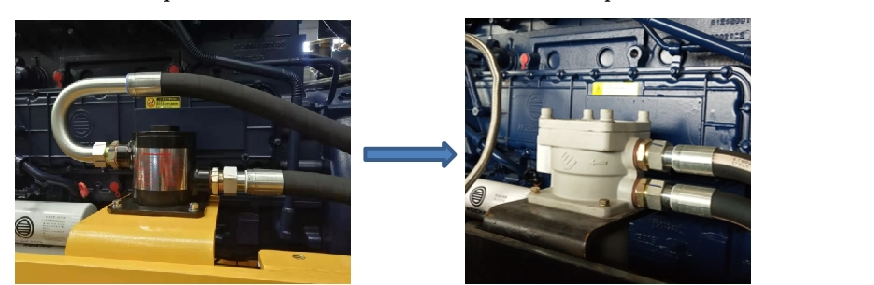

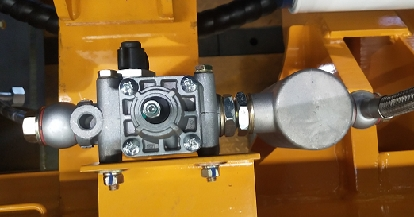

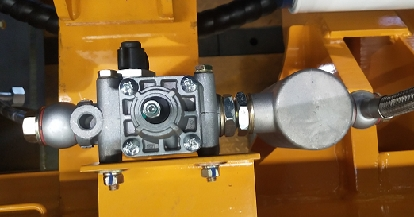

The pilot operated model cancels the form of pilot pump +D32 hydraulic multi-way valve, and changes to the configuration of pilot accumulator+hydraulic solid valve; which flexible shaft and pilot operated pipelines have higher universality.

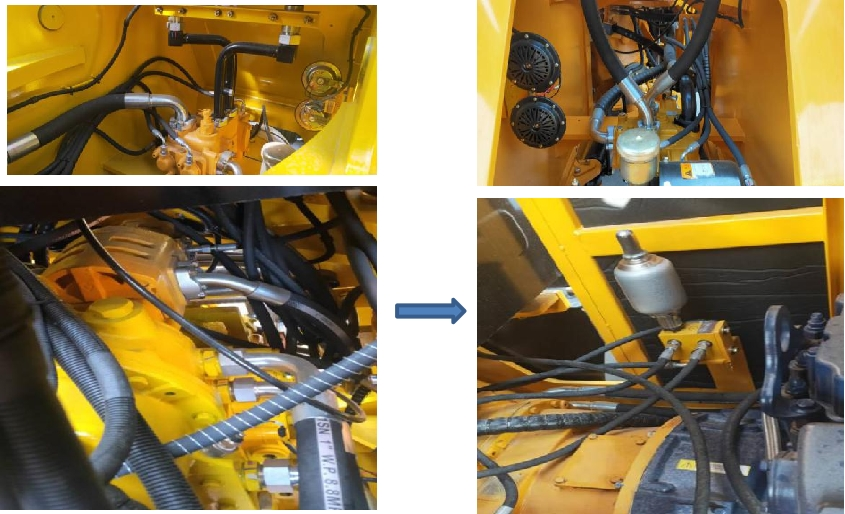

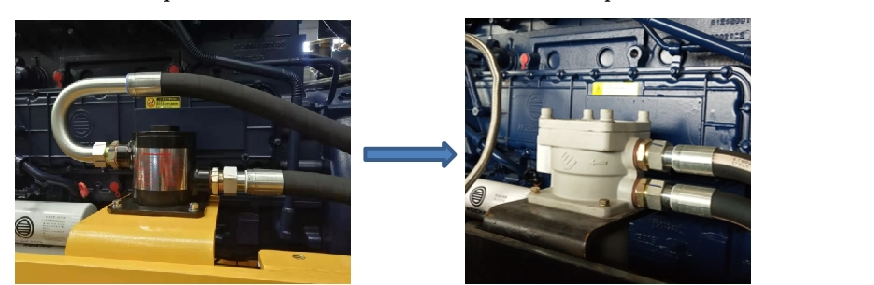

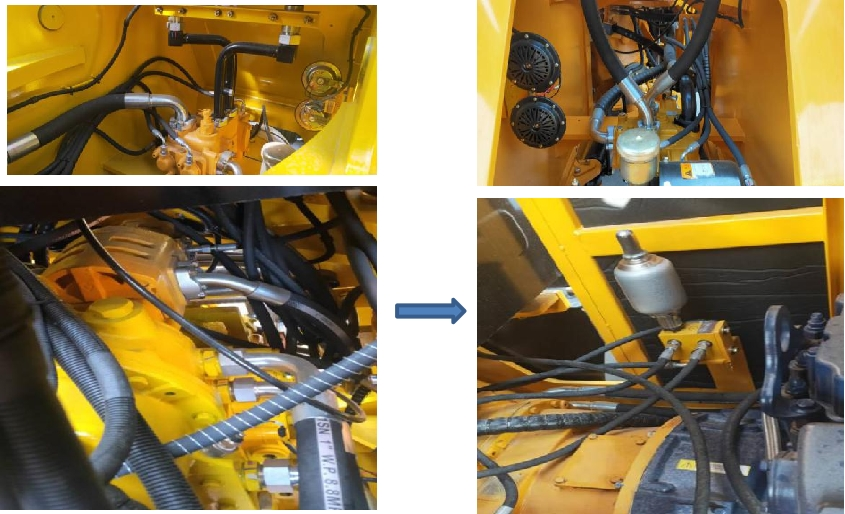

10.Braking - Hydraulic components, pipelines

10.1.pipeline improvement

The sealing mode of brake caliper and brake steel pipe is changed from copper pad to O-ring, which makes the sealing mode more reliable.

10.2.Hydraulic components improvement:

10.2.1. The booster pump is placed at the front of the front frame, which is convenient for filling brake fluid. And the DOT4 brake fluid of hightening oil cup air tank to reduce the oil spill phenomenon.

10.2.2. The air pressure source manager, which convenient to maintenance.

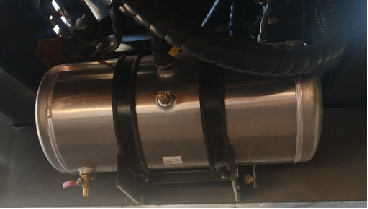

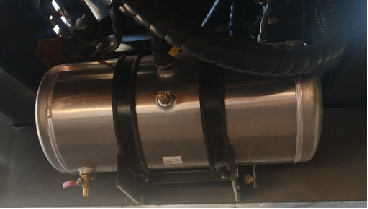

10.2.3. Aluminum alloy air tank to reduce system corrosion.

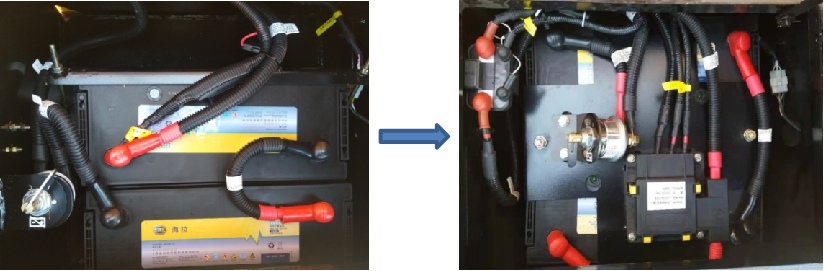

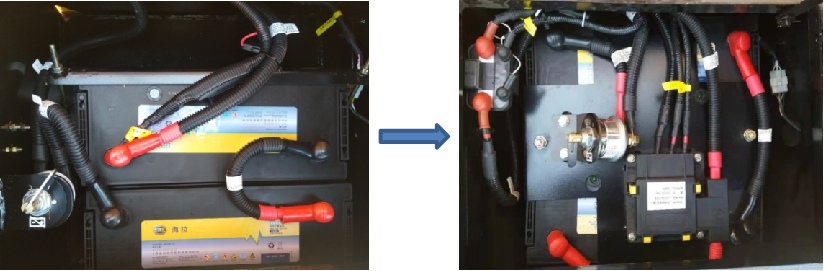

11.Electrical device improvement

11.1.Upgrade of electrical components:

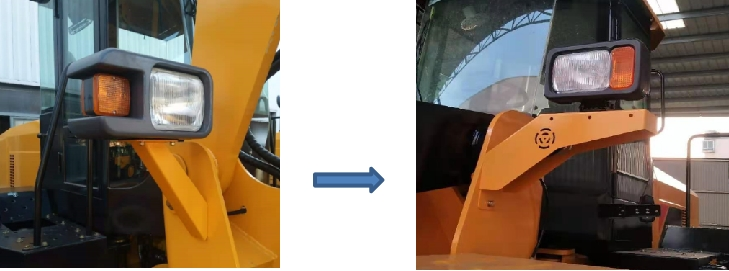

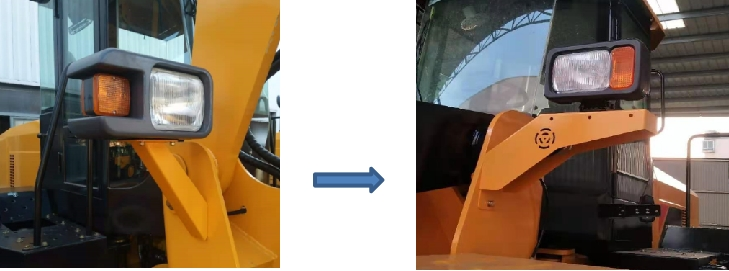

11.1.1. Front combined headlight

The bulbs of high-beam and low-beam lamps adopt domestic famous brands OSRAM and Philips.

Which is ibration performance, heat and water resistance meet the relevant national standards.

11.1.2. Oil temperature sensor

Adopt high resistance thermosensitive material and waterproof connector of DT system.

11.2.Optimization of circuit layout of electrical devices;

Equipped with waterproof fuse box specially used for construction machinery, it not only ensures stable operation of electrical system, but also facilitates maintenance.

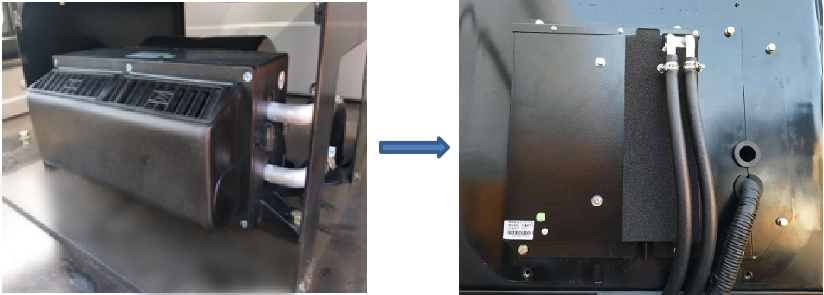

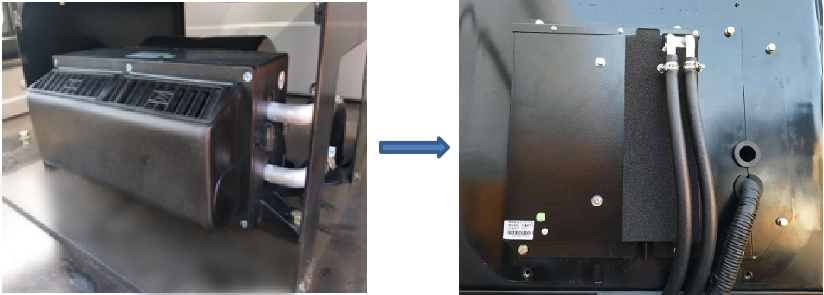

11.3.Optimization of heater system:

11.3.1. Optimize the warm air duct, and use glass for defogging and defrosting

11.3.2. The heating power is increased to improve the driver's comfort.

Jingong loader newly updated model JGM757KV is a brand-new product which is comprehensively upgraded and built on the basis of Jingong classic model JGM757K & JGM757KN, adhering to the reliability essence of JGM757K & JGM757KN, with 5 big upgrades and 35 improvements, the cab is more luxurious and comfortable, the performance is more stable, the operation is more comfortable, fast, safe and convenient. It will be the representative of the new generation of heavy-duty loaders.

Main Parameters

Item | JGM757KV |

Bucket capacity (m3 ) | 2.3~3.6 |

Rated load (㎏) | 5000 |

Operating weight(㎏) | 17300 |

Max. dumping height(mm) | 3100 |

Max. dumping distance(mm) | 1220 |

Wheelbase(mm) | 3230 |

Wheel track(mm) | 2240 |

Ground clearance(mm) | 400 |

Overall length(mm) | 7782 |

Overall height(mm) | 3410 |

Bucket width(mm) | 2900 |

Dumping angle (°) | 45 |

Max. breakout force (kN) | ≥170 |

Max. traction force (kN) | ≥145 |

Min.turning radius (㎜) | 6250 |

Turning radius(at outside of tire) (㎜) | 6550 |

Boom lifting time (S) | 6.3 |

Total cycle time (S) | 12 |

Engine | Model | Weichai WD10G220E23 |

Type | Six cylinders, in-line, water-cooled, four-stroke, direct injection. |

Rated power(KW) | 162 |

Rated speed(r/min) | 2000 |

Travel speed(Km/h) | F1/R1 | 11.5/16 |

F2/R2 | 36/- |

F3/R3 | - |

F4 | - |