Construction equipment is rapidly evolving to become greener and cleaner. Around the world, jobsites are seeing an increase in government regulations for low emissions and quiet zones where internal combustion engines are either limited in use or completely banned. In response, manufacturers are designing and producing environmentally friendly machines to meet these requirements.

Government policies and market trends are seeking to reduce the use of combustion engines in both on-road and off-road applications to address climate change and mitigate air pollution.

JinGong has a really strong commitment to meeting the requirements of the Paris Agreement on climate change and reducing carbon emissions. We also see a strong ambition in our customers’ roadmaps towards the reduction of their emissions. Increasing emission incentives and zero-emission targets coming into play in recent years have had a marked effect on the increase in electric equipment.

1、JGM857E Specifications

1.1 Power Battery

CATL Lithium iron phosphate battery Energy recovery system, longer endurance and more energy saving.

Equipped with large-capacity lithium iron phosphate battery, optional charging pile specification: 240KW, using double gun charging, it can be fully charged in 1 hour. The battery has its own heating and cooling system. The battery adopts intelligent temperature control and liquid cooling, which can ensure the best working temperature of the battery in real time, which is beneficial to guarantee the battery life.

1.2 Motor Control

CRRC Permanent magnet synchronous motor,High torque, high power

Low noise, small vibration, Quick start, more comfortable Waterproof and dustproof, Insulation maintenance.

The whole machine adopts dual-motor system drive scheme, The oil pump motor and the walking motor can be separated to achieve independent control, which is more powerful and energy-saving.

1.3 Transmission & Axles

Adopts a 60-loaded fixed-axis gearbox with more gear shifts, and uses a variety of transmission ratios to implement different walking speeds and traction forces to meet the needs of various operating speeds and operating conditions.

Adopts upgraded Jingong heavy-duty 50E drive axle, equipped with four planetary gears, with high structural strength, large carrying capacity, long service life and high reliability.

1.4 Radiator

The water cooling system is divided into two channels, one has a water resistance of 125kpa, and the other has a water resistance of 130kpa. The pump is selected according to the maximum water resistance. The total water flow is greater than 53L/min at a head of 13 meters. There is a certain inverse relationship between the shunt and the water resistance. The resistance value is the same, the water flow can reach 25L/min, and the pump power is 235w;

The heat dissipation power of the hydraulic oil radiator is 15kw, which meets the requirements.

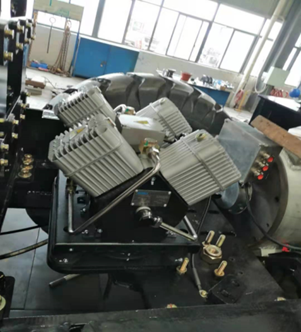

1.5 Air compressor

The oil-free piston engine is an all-oil-free piston air compressor. Adopts advanced technology and strong technical strength to produce air compressors with high reliability, high economic efficiency and high quality. The product has compact structure, light weight, stable and reliable operation, low noise and easy installation. It is a new generation of safe, environmentally friendly and energy-saving air compressors.

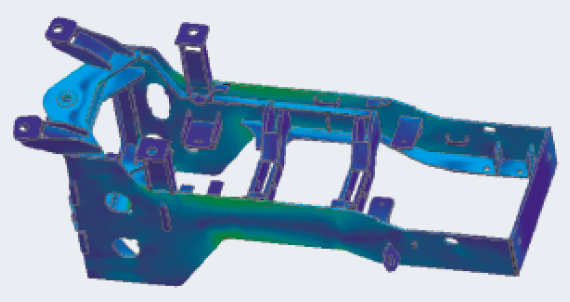

1.6 Frame

The wheelbase extended to 3300mm, and the rear suspension distance is increased. The front and rear axle load distribution are more reasonable and stability. The reliability of the frame is greatly improved through finite element simulation analysis.

1.7 Safty

Battery system protection level: IP67.

The motor adopts intelligent temperature control and liquid cooling. Ambient temperature: -30~+70℃, Protection level: IP67, Altitude ≤5000m.

1.8 Pilot Operation

Efficient conversion and comfortable operationElectronically controlled pilot hydraulic system, oil supply on demand,Double pump confluence.

1.9 Economy

Cost saving USD 68620 per year per set.

1.10 Carbon Emission

Pure Electric Wheel Loader:zero emission.

Carbon emisson saving 187.8 ton/year/set.

1.11 Cabin

JGM857E loader adopts Jingong developed brand-new cab, which is luxurious, open-view, beautiful and practical.

2、JGM857E(351KWH) Electric Wheel Loader Parameters

No. | Item | Unit | JGM857E | ||

1 | Bucket Capacity | m3 | 2.7-4.5 | ||

2 | Rated Load | kg | 5500 | ||

3 | Operating Weight | 19400 | |||

4 | Dumping Height | mm | 3760 | ||

5 | Dumping Distance | 1220-1550 | |||

6 | Wheelbase | 3300 | |||

7 | Wheel track | 2290 | |||

8 | Ground Clearance | 408 | |||

9 | Turning Angle | Left | ( °) | 38 | |

Right | 38 | ||||

10 | Overall Length | mm | 8200-8850 | ||

11 | Overall Width | 2990 | |||

12 | Overall Height | 3530 | |||

13 | Height when Max. bucket lifting | 5470 | |||

14 | Distance between rear axle to hinge | 1685 | |||

15 | Rear overhand length | 2180 | |||

16 | Departure Angle | ( °) | 30 | ||

17 | Rear axle lateral swing angle | 10 | |||

18 | Turning diameter | mm | 6670-7050 | ||

19 | Diameter of traverse | 7140-7570 | |||

20 | Max traction | kN | >175 | ||

21 | Max grade ability | ( °) | 30 | ||

22 | Lifting ability | kN | 81.3 | ||

23 | Tipping load | >100 | |||

24 | Max breakout force | kN | ≥175 | ||

25 | Implement System | Lifting | s | ≤5.1 | |

Lowering | ≤3.2 | ||||

Dumping | ≤1.2 | ||||

Total Cycle Time | ≤9.5 | ||||

26 | Travel Speed | Forward Ⅰ/Ⅱ/Ⅲ/Ⅳ | km/h | 9/18/29/38 | |

Reverse Ⅰ/Ⅱ/Ⅲ/Ⅳ | 9/18/29/38 | ||||

27 | Electricity Consupton per hour | KWh | 35-45 | ||

28 | Endurance Time(General Working condition) | h | 7.5-8.5 | ||

Endurance Time(Heavy duty working condition) | h | 6.5-7.5 | |||